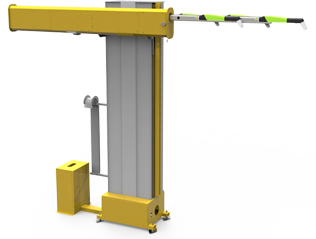

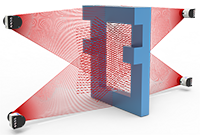

? The controller of the paddle level switch adopts the principle of electromechanical potential control. When there is no material in the blade part of the silo, the paddle level switch is powered on, the indicator light is on, and the blade rotates counterclockwise; when there is material in the blade part of the silo, the blade rotation is blocked, the control signal is converted, and the power supply of the paddle level switch motor is disconnected until there is no material in the blade part, and the paddle level switch automatically resets. At this time, the motor power is connected, the indicator light is on, the blade starts to rotate, and the control signal is switched, and this cycle repeats;

? Not affected by dust, dielectric constant, sticky material, temperature and pressure changes.

? Suitable for almost all solid materials.

? Simple and reliable working principle, modular design, maintenance-free.

? Highly integrated mechanical seal to prevent dust from penetrating along the shaft.

? Unique friction clutch mechanism to protect the motor from damage.

? A variety of process connections can be used, and installation is simple.

? Blade speed: counterclockwise 1R.P.M (rev/min)

? Rotation torque: 4.9N·M

? Insulation resistance: >100MQ (500VDC)