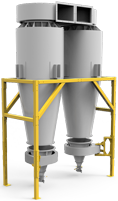

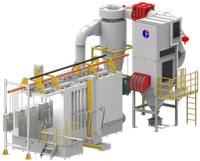

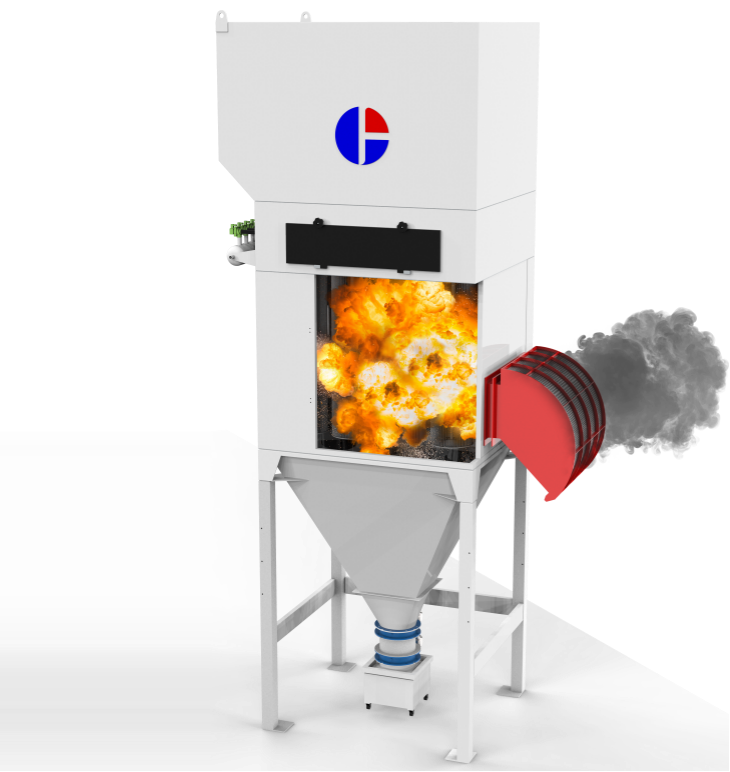

? The air-locking ash unloading adopts the original dust removal back stage, and the overall equipment is raised by 1800mm. The dust collector ash hopper is added with an ash unloading belt operation monitoring interlock.

? Monitor the operation status of the ash unloading valve; if the ash unloading valve fails or the ash unloading valve is blocked and does not operate, the system alarms and interlocks;

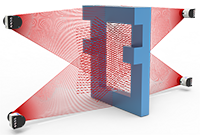

? After a special sealing design, it provides effective isolation between the inlet and outlet;

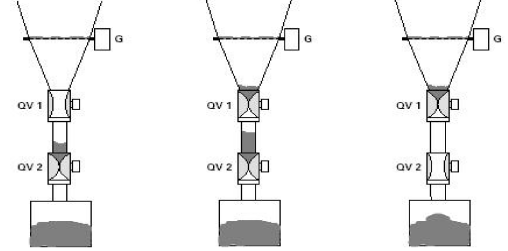

? The working principle of the double-gate butterfly valve air-locking ash unloading:

1) The upper pneumatic butterfly valve-QV1 is opened.

The recovered powder falls into the middle pipe through the upper valve-QV1.

- The lower valve-QV2 is in a closed state.

2) The upper valve-QV1 is closed.

3) The lower valve-QV2 is opened.

- The upper valve-QV1 is in a closed state.

4) The lower valve-QV2 is closed.

- After a short delay, the upper valve-QV1 is opened again.

- The working process is carried out continuously from 1) to 4).

? The dust collector can be isolated from the powder in the collection bucket to achieve the purpose of locking the air unloading valve. All butterfly valves are pneumatically controlled and completely explosion-proof. It can also avoid problems such as agglomeration and jamming of the rotary type split type air lock ash unloading valve.